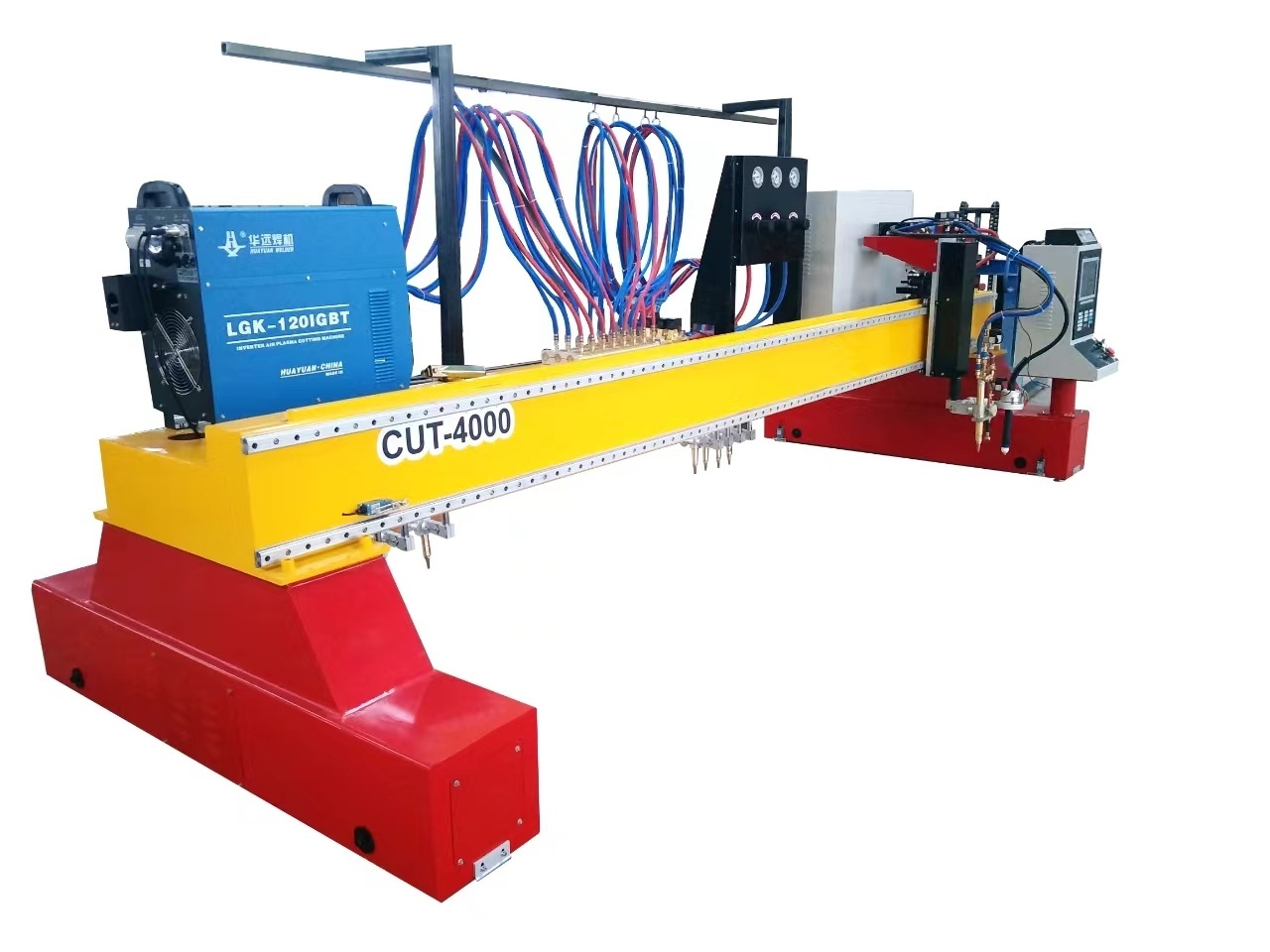

PVC gasket extrusion line

IT’S USED FOR PRODUCE SEAL GASKET OF PVC, TPE MATERIAL. MAIN MATERIAL ARE PLASTIC AS MAIN CONTENTS.

key word:

Category:

Plastic Extrusion Machine

E-mail:

PVC gasket extrusion line

Specification

- Φ45/65 extruder

- Machine frame

It is made of steel and plate welded and treated by return stress. It has high steel property and small deformation

- Gear box

The product design adopts the specified technical specification, the gear and shaft parts are made of high strength alloy steel, the gear precision is high, the tooth surface hardness is good, the output end of the hollow shaft is equipped with super-specification thrust bearing, bearing the back thrust of the screw, the main standard parts such as bearing and oil seal are all used domestic high quality products, the whole machine has high bearing capacity, stable transmission, low noise and high efficiency.

A. deceleration ratio :16:1

B. input power : 7.5/15 kw

C. use hard tooth surface grinding gear, low noise and high life, reliable operation

D. forced oil circulation lubrication system

- Barrel and Screw

A. barrel and screw material are 38 CrMoAlA high quality nitrided steel

B. nitrided layer depth :0.4-0.7 mm, nitrided hardness: screw 850 HV, barrel 930 HV:

C. screw diameter : 45/65mm

D. screw structure: special type

E. screw speed: 10-80 r/min

F. Surface roughness of screw edges G.:0.4 um

G. inner surface roughness :0.4 um

- Heating System

A. heating power: 7.5KW/15KW Type Y

B. heating power :3- AC380V,50HZ,

C. total heating power :~24 kw

D. rotate speed: 1500rpm

- Cooling device

Indirect cooling of circulating water

- Main motor

A. motor power: 7.5KW/15KW model Y

B. motor and main engine installed, running stable vibration small

C. Power :3- AC380V,50HZ,

D. motor synchronous speed 1500 rpm

- Electric control cabin

A. speed controller: variable frequency speed control stepless speed control

B. Temperature Control Area: Digital Intelligent Temperature Control Instrument

C. Contactor: Delixi

D. Power :3- AC380V,50HZ

|

|

Model |

SJ-45 |

SJ-65 |

|

1 |

application |

PVC/ TPE granule Product: soft PVC and TPE material Output: 20-30Kg/h |

PVC/ TPE granule Product: soft PVC and TPE material Output: 40-60Kg/h |

|

2 |

Material feeding method |

Manual |

|

|

3 |

Barrel screw material |

38GrMoAcA High quality nitride steel |

|

|

4 |

Nitriding depth |

0.4-0.7mm |

|

|

5 |

The surface hardness of the barrel and screw |

Screw: 850HV barrel: 930HV |

|

|

6 |

Screw diameter |

45mm |

65mm |

|

7 |

Output |

20-30kg/h |

40-60kg/h |

|

8 |

Barrel heating mode |

Cast Al heating ring heating |

|

|

9 |

Cooling mode of main machine |

low-noise fan cooling/4zone |

|

|

10 |

Power |

15kw |

22kw |

2. Extrusion mould

Die head type: Internal pressure type

Material die head and moulds: High quality die steel, 40Cr

Mould structure: the die、mandrel can be exchanged

Head heating: 2 zones

3. Cooling water tank

Length of the tank: 3000mm

Material of the tank: stainless steel

Move from forward & backward: power driven

Power of moving motor: 0.55KW

4. Belt type haul-off machine

|

1 |

Motor power |

0.55kw |

|

2 |

belt |

ribbed belt |

|

3 |

Wheel diameter of each ribbed belt |

Φ90mm adopt 480H |

|

4 |

Hauling speed adjust method |

Frequency converter regulation |

|

5 |

Main power |

3 phase 5 wires AC380±10% 50Hz |

5. Rewinder

|

1 |

Number of wire arrangers |

1 |

|

2 |

Power of motor |

0.75kw |

|

3 |

voltage |

380V 50/60Hz |

Previous

UPVC Window Profile Extruder Machine window machine

MESSAGES