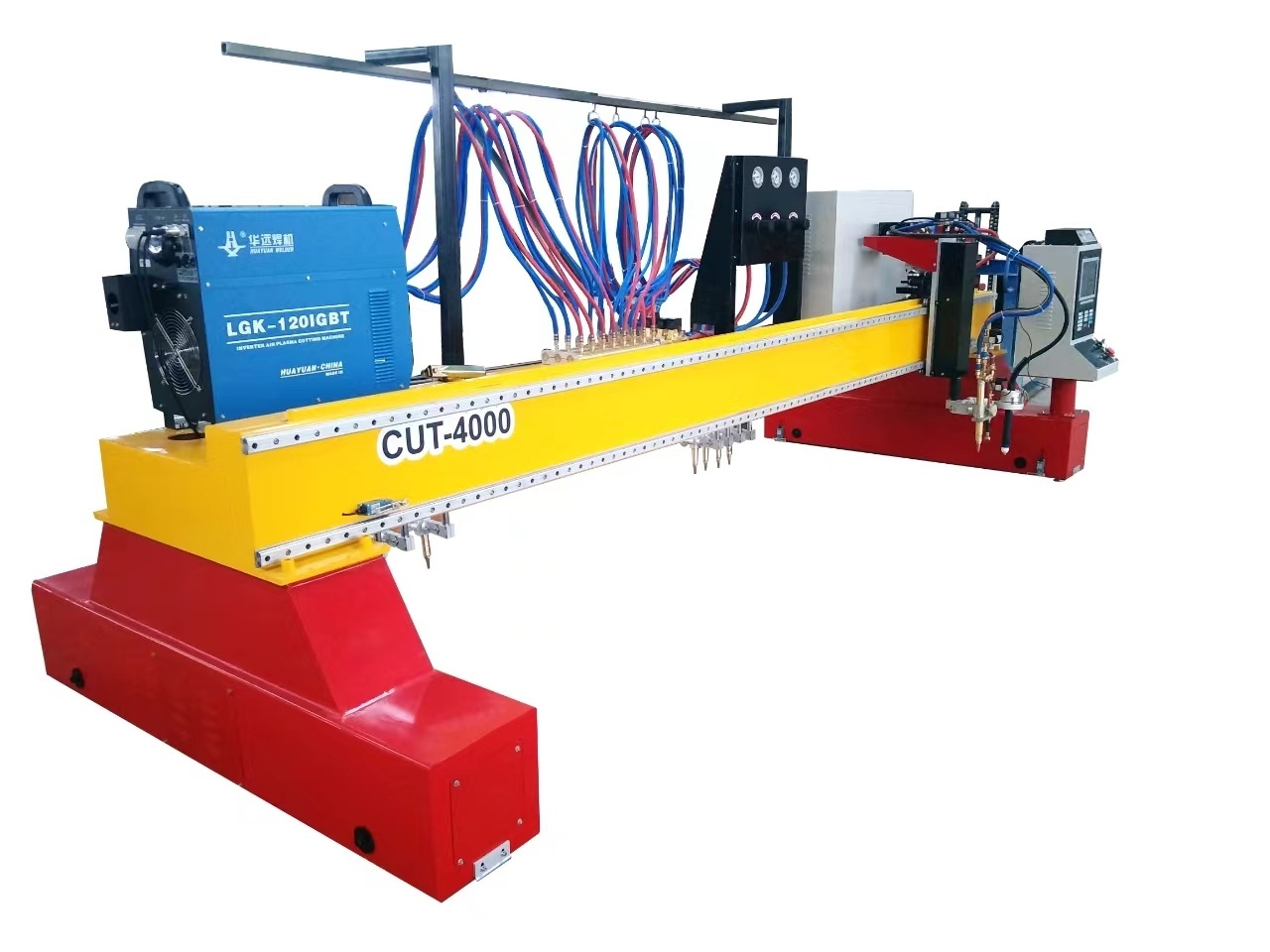

U/Box Beam Assembling Machine LFUZ12

The U/Box Beam Assembling Machine is a specialized equipment used in the construction industry for assembling and fabricating U-shaped or box-shaped beams. It is designed to efficiently and accurately join the different components of the beams, such as flanges and web, to create a strong and sturdy structure. This machine is capable of handling beams of various sizes and shapes, making it versatile and adaptable to different construction projects. It is equipped with advanced technology and precision components to ensure the beams are assembled with high quality and accuracy. The U/Box Beam Assembling Machine is easy to operate and requires minimal manual intervention, reducing the risk of errors and increasing productivity. It is an essential tool for construction companies looking to streamline their beam fabrication process and deliver superior quality structures to their clients. With its efficiency and reliability, this machine is a valuable asset for any construction project.

key word:

Category:

H Beam Assembling Welding Straightening Integral Machine

H beam Assembly Machine

E-mail:

U/Box Beam Assembling Machine LFUZ12

U/Box Beam Assembling Machine

Main Function:

This is the special equipment for bottom plate ,web plate and baffle plate of box beam .It is composed of main machine, roller conveyor, centering device, positioning device, hydraulic system and electric control box .

Features:

1.The two moving boom have one motor reducer for each, driving the four moving wheel working ,which form double driving system and make sure working stable.

2.It adopts hydraulic system for clamping the work-piece with big clamping force.

3.For the up and down clamping oil cylinder, it adopts floating clamping cylinder, it has the advantage that the force of clamping work-piece won’t delivered to the conveyor, which can avoid the damage of conveyor due to the big clamping force for work-piece.

4.It adopts work-piece centering and positioning device, centering device and positioning device have one group 3pcs for each, staggered installed on the roller conveyor, which can realize the positioning and centering of work-piece.

5.The electric control system is composed of electric control box and operation box. The electric control box install on the platform, two operation boxes install on the two side of column. They are placed separately, which is convenient for operation.

Technology Parameter:

|

Model |

LFUZ12 |

LFUZ15 |

|

Workpiece size (mm) |

300-1200 |

300-1500 |

|

Workpiece thickness (mm) |

≤80 |

|

|

Max. loading capacity |

20 T |

|

|

Gantry travel speed (m/min) |

4/6 |

|

|

Hydraulic pressure (Mpa) |

16 |

|

|

Max. pressure of both side cyliner (T) |

15 |

|

|

Max. pressure of Up Cylinder (T) |

30 |

|

Product display

Previous

Plate Drilling machine CNC Drilling machine PCD2016/2

MESSAGES