Plate Drilling machine CNC Drilling machine PCD2016/2

A plate drilling machine, also known as a CNC drilling machine, is a precision tool used for drilling holes in metal plates with accuracy and efficiency. Equipped with a computer numerical control (CNC) system, these machines can programmatically drill holes of various sizes and patterns on large plates.

key word:

Category:

CNC High Speed H Beam Drilling Machine

H Beam Assembling Welding Straightening Integral Machine

H beam Assembly Machine

Boiler/Pressure Vessel/Heat Exchanger/Air cooler CNC Drilling Machine

Flange hole Drilling Machine

Larger Steel Plate CNC Drilling Machine

ElectricTower Processing Machine

High speed punching and drilling integral production line

E-mail:

Plate Drilling machine CNC Drilling machine PCD2016/2

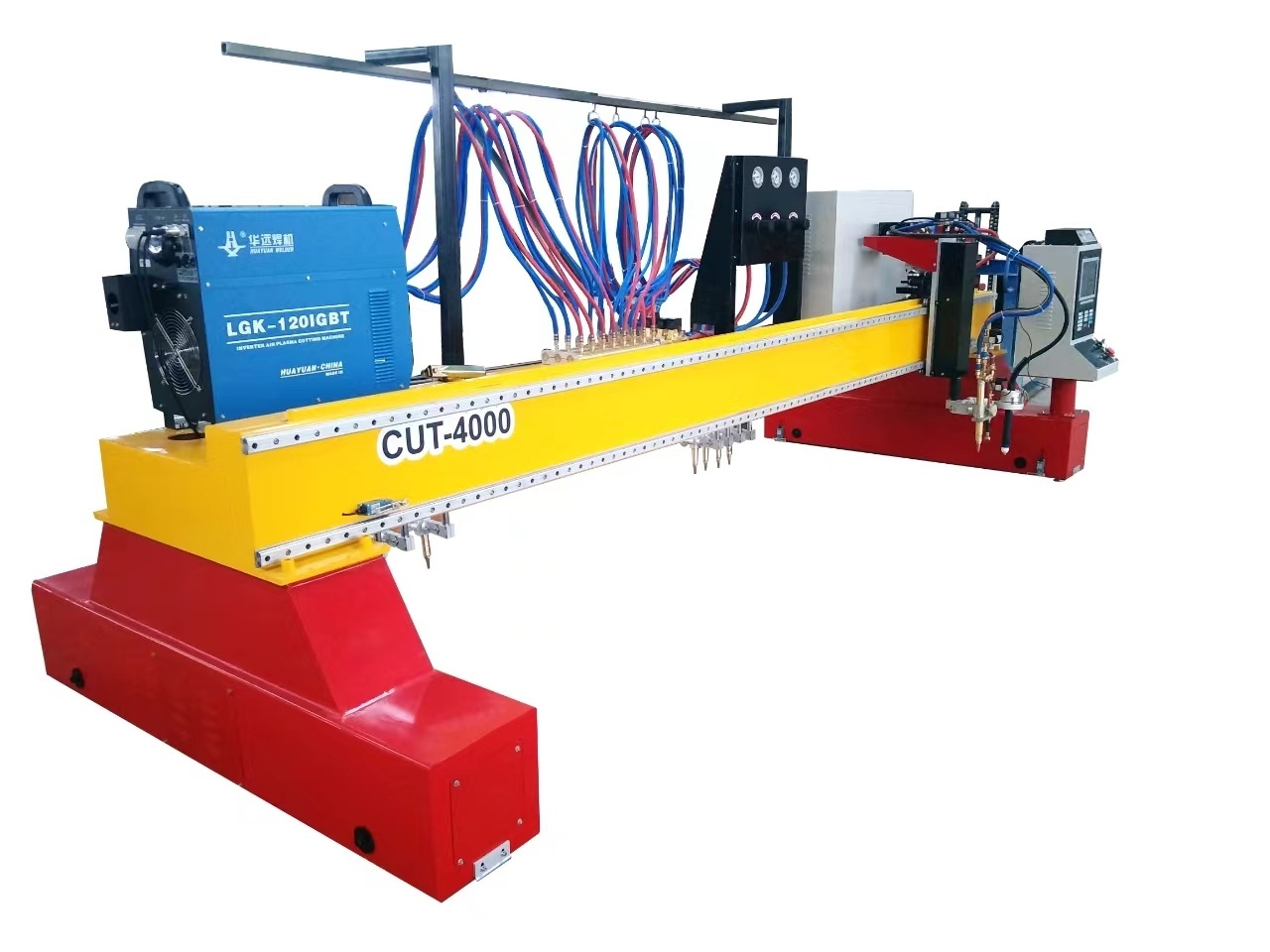

PCD series CNC Gantry plate drilling machine CNC Drilling machine

A plate drilling machine, also known as a CNC drilling machine, is a precision tool used for drilling holes in metal plates with accuracy and efficiency. Equipped with a computer numerical control (CNC) system, these machines can programmatically drill holes of various sizes and patterns on large plates. Plate drilling machines are commonly used in industries such as steel fabrication, construction, and shipbuilding for tasks like creating holes for bolts, rivets, or connections.

Apply scope of Plate Drilling machine CNC Drilling machine:

For steel structure, tower, bridge, mechanical processing and other industries of the connecting plate, baseboard drilling processing.

Product structure of Plate Drilling machine CNC Drilling machine:

Casting bed, spindle hydraulic feed, SEW motor reducer, workpiece automatic clamping.

This machine is mainly composed of bed, gantry structure, drilling power head, hydraulic system, control system, centralized

lubrication system, cooling system chip removal system and quick change chuck.

The characteristics of Plate Drilling machine CNC Drilling machine:

1.The bed is made of high quality gray cast iron with stable performance and no deformation.

2.Spindle hydraulic feed, motor adopts German SEW reducer motor, high efficiency and very durable.

3.Adopt hydraulic clamping system, small workpiece can be clamped at four corners of worktable, shortening production

preparation period and improving production efficiency.

4.SIEMENS servo motor + CNC system control, Lgantry mobile dual servo motor + ball screw synchronous dual drive.

Technical parameters:

|

|

Model |

Unit |

PCD2012 |

PCD2016 |

PCD2016/2 |

PCD 2020 |

PCD2020/2 |

PCD3016 |

PCD3016/2 |

||||

|

Processing size |

L×W |

mm |

2000x1200 |

2000x1600 |

2000x2000 |

3000x1600 |

|||||||

|

Superimposed thickness |

mm |

15-100 |

|||||||||||

|

Drilling spindle |

Quan. of spindle |

个 |

1 |

1 |

2 |

1 |

2 |

1 |

2 |

||||

|

Model of spindle |

|

Morse taper4# |

|||||||||||

|

Speed of spindle |

r/min |

120-560 Infinitely variable speed |

|||||||||||

|

Feeding way |

|

Driller driven by the hydraulic control stroke |

|||||||||||

|

Feeding stroke |

mm |

180 |

|||||||||||

|

Drilling dia. |

mm |

Φ12-Φ50(Optional: Φ12-Φ63) |

|||||||||||

|

Power of main motor |

KW |

5.5(Optional7.5) |

|||||||||||

|

Hydraulic clamp |

Quan. of clamping cylinder |

支 |

12 |

||||||||||

|

Clamping force/pcs |

KN |

7.5 |

|||||||||||

|

Clamping way |

|

Double side button control in Gantry |

|||||||||||

|

Pressure of hydraulic pump |

MPa |

6 |

|||||||||||

|

Volume of oil tank |

L |

100 |

|||||||||||

|

Electrical control |

Control mode |

|

Siemens control system /PLC+ Host computer |

||||||||||

|

X-axis servo motor |

KW |

1.5 |

2x1.5 |

2x1.5 |

2x1.5 |

2x1.5 |

2x1.5 |

2x1.5 |

|||||

|

Y-axis servo motor |

KW |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

|||||

|

Drilling precision |

Precision of position |

mm |

±0.2mm |

±0.2mm |

±0.2mm |

±0.2mm |

±0.2mm |

±0.2mm |

±0.2mm |

||||

|

|

Precision of repeating position |

mm |

±0.1mm |

±0.1mm |

±0.1mm |

±0.1mm |

±0.1mm |

±0.1mm |

±0.1mm |

||||

|

Cooling mode |

|

Forced circulation water cooling |

|||||||||||

|

Chip removal method |

|

Flat chain automatic chip conveyor |

|||||||||||

|

Dimension |

LxWxH |

mm |

3160x2200x2370 |

3160x2400x2370 |

3160x2800x2370 |

4160x2400x2370 |

|||||||

|

Weight of machine |

T |

5.2 |

7 |

7.5 |

8.5 |

9 |

9.5 |

10 |

|||||

Previous

Gantry Movable Three-dimensional Drilling machine

MESSAGES