CNC Rolling compound machine for thermal break aluminum profile

it is used to press and fasten the Aluminum profile with thermal bridging strips

key word:

Category:

Industrial Aluminum Profile Machine

E-mail:

CNC Rolling compound machine for thermal break aluminum profile

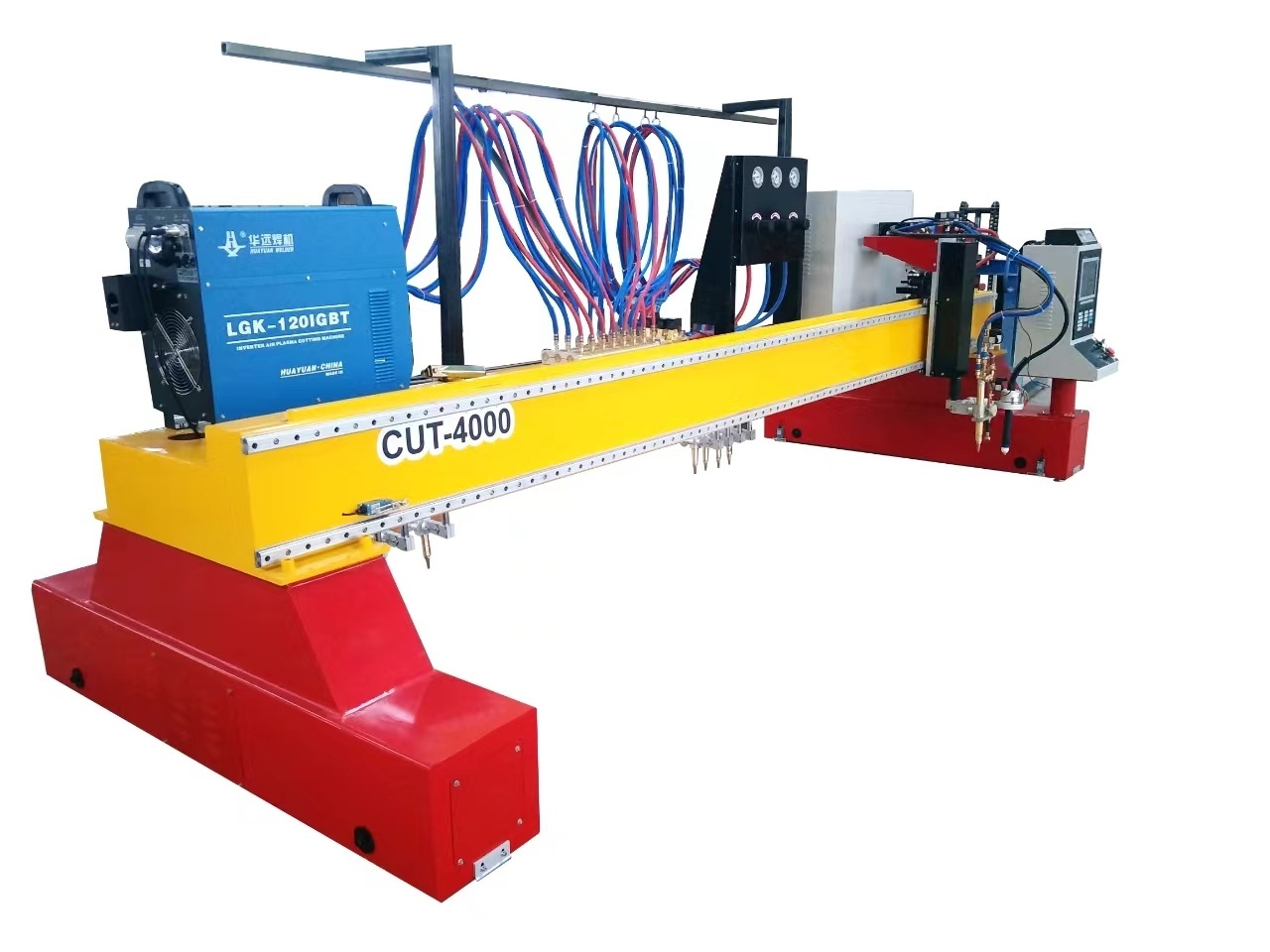

CNC Rolling compound machine for thermal break aluminum profile RC2-CNC-230

Main usage and using range

The machine is the special equipment for manufacturing thermal bridging profile, aluminum and PVC composite profile. With three groups of carbine hobbing wheel, it is used to press and fasten the profile with thermal bridging strips, and PVC profile.

Features:

Adopt imported CNC control system, advanced LED touch screen. built in special software into CNC system. It complete to save two axis data of compound all kinds of aluminum profile, loading operation easy.

Adopt 2 axis CNC control system: it used to control hobbing plate height, pressing roller height, it’s easy to complete the height adjustment for processing different aluminum profile.

Working principle

Adjust the hobbing cutter into the notch of profiles and draw the profile by rotating the cutter, and thus press and fasten the two sides of the profile

Specification

|

Power Voltage |

380v 50Hz |

Feeding speed of profile |

0-90m/min frequency control |

|

Total power |

4.5kw |

Max processing size of profile (W*H) |

280×380mm |

|

Rolling wheel diameter |

230mm |

Contour size |

1600×1000×1600mm |

|

Distance of hopping plate at same shaft |

0-100mm |

Net weight |

1500kg |

|

Front and back distance of each group of hobbing wheel |

0-260mm |

|

|

Previous

CNC Aluminum profile Rolling and Bending machine

MESSAGES