Punching &Marking &Shearing Machine for Channel / Flat

key word:

Category:

ElectricTower Processing Machine

E-mail:

Punching &Marking &Shearing Machine for Channel / Flat

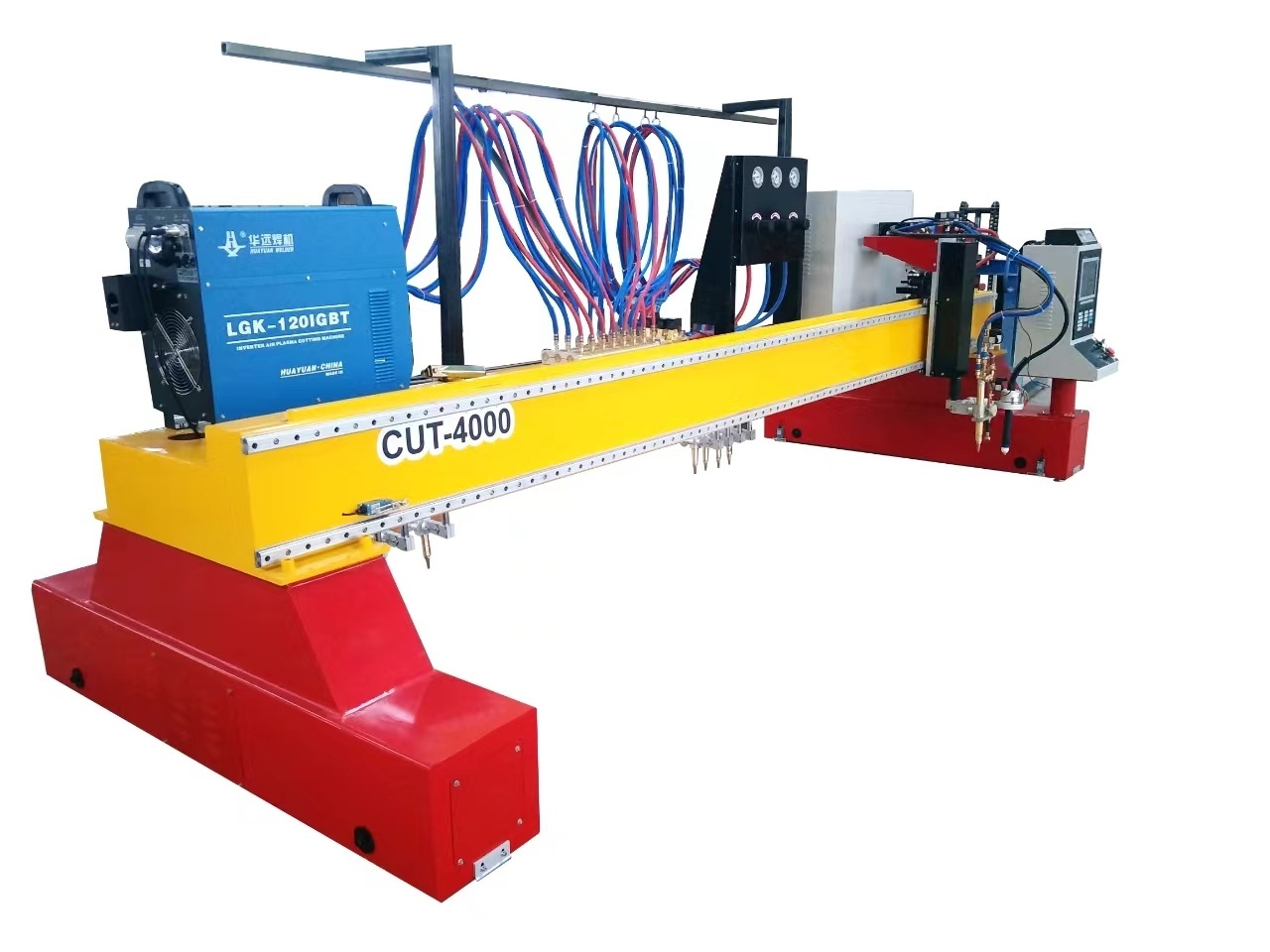

BP Series of Punching &Marking &Shearing Machine for Channel/ Flat

This machine is the integrated punching, typing and shearing for the channel and plate.

This machine connect with the hoop production machine to produce the hoop which is used in power construction.

Technology parameter

|

Model |

|

BP1410P |

BP1410E |

|

|

Processing size |

Plate steel size(mm) |

40-140 |

40-140 |

|

|

Channel size(mm) |

8#; 10#; 12#, 14# |

8#; 10#; 12#, 14# |

||

|

Thickness of workpiece (mm) |

10 |

10 |

||

|

Length of workpiece (mm) |

6000(Customizable) |

|||

|

Punching ability |

Punching Dia. (mm) |

Φ26; Long hole: Φ22x50 |

Φ26; Long hole: Φ28x50 |

|

|

Punching force |

800kN |

|||

|

Qty. of punch |

3pcs on every side, total in two sides: 6pcs. |

|||

|

Typing ability |

Typing force |

700KN |

||

|

Quan. of typing dies |

4pcs |

|||

|

Size of the word(mm) |

14×10×19 (can be made as the requirement of the customer) |

|||

|

Quan. of words |

12pcs |

|||

|

Shearing |

Shearing force |

800kN |

||

|

Shearing mode |

In the flat end is cut with the single blade; In the arc end shear with double-edged cutter. Pls note: can not cut channel steel. |

|||

|

Qty. of axis |

3pcs |

|

||

|

Feeding mode |

CNC trolley feeding the materials |

|||

|

Feeding speed |

50-80m/minutes |

|||

|

Unloading mode |

Pneumatic |

|||

|

Processing accuracy |

Meet the requirement in GB2694-2010 |

|||

|

Programming mode |

Keyboard input, RS232 interface input, USB interface |

|||

|

Program function |

Fault language display |

|||

|

The total power (KW) |

About 21 |

|||

|

Dimension of the machine(m) |

28000×5500×2500 |

|||

This production line is composed by six parts: workpiece loading part, feeding part, host machine, finished workpiece unloading part, electrical control part, hydraulic power part.

1.This machine is a integrates for processing channel steel and flat steel with the advantages of wide range of application and high production efficiency.

2.In the flat end is cut with the single blade; In the arc end shear with double-edged cutter.

3.Adopt CNC technology to control the processing of the machine, feeding with the servo motor, high efficiency and stable accuracy.

4.it can connect with Steel hoop molding machine to produce the hoop which is used in the power construction.

5.According to the customer’s requirement it can realize the function of Intelligent link.

Previous

Channel 3-side Punching machine

MESSAGES