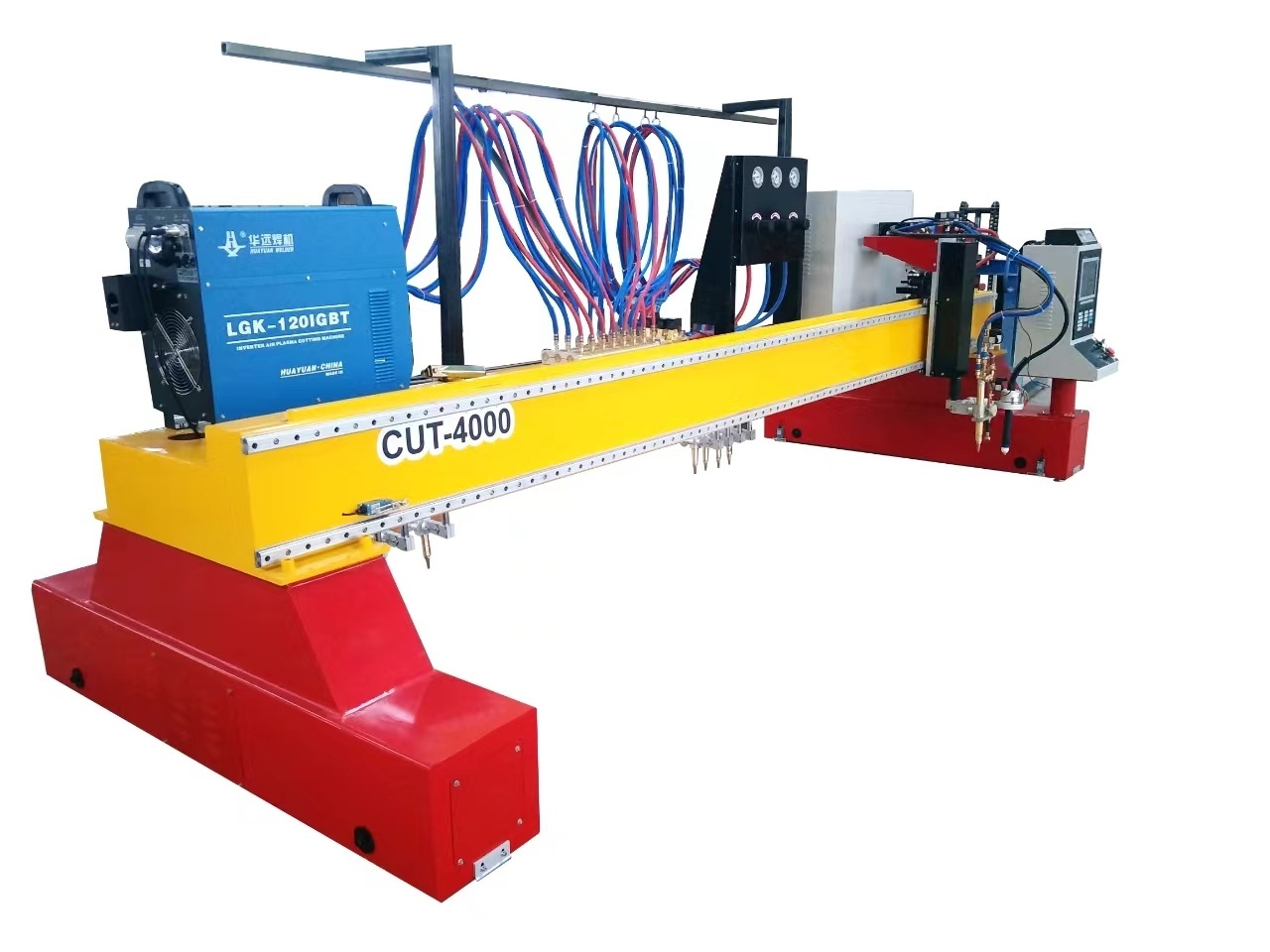

CNC Drilling and Milling Machine for Aluminum Profile

The CNC Drilling and Milling Machine for Aluminum Profile is a specialized tool used for precision drilling and milling of aluminum profiles. Commonly employed in industries such as aluminum fabrication, window and door manufacturing, and curtain wall construction, it offers efficient and accurate processing of aluminum profiles.

key word:

Category:

Aluminum Window and Door Machine

Industrial Aluminum Profile Machine

E-mail:

CNC Drilling and Milling Machine for Aluminum Profile

CNC Drilling and Milling Machine for Aluminum Profile

The CNC Drilling and Milling Machine for Aluminum Profile is a specialized tool used for precision drilling and milling of aluminum profiles. Commonly employed in industries such as aluminum fabrication, window and door manufacturing, and curtain wall construction, it offers efficient and accurate processing of aluminum profiles. This machine is equipped with advanced CNC technology to ensure precise hole drilling and milling operations, enhancing productivity in processes requiring precise machining of aluminum profiles for various structural and assembly applications.

Equipment Features

1. This equipment is used for the processing of aluminum profiles, aluminum wood composite profiles and UPVC profiles.

2. Take the lead in using the gear flip design, one clamping can complete the rapid switching between 0 degrees, -90 degrees and 90 degrees, so that the work efficiency is greatly improved.

3. Various interfaces are simple and intuitive, easy to operate.

4 3 kinds of programming methods: international standard G code programming, library programming, CAD drawing import programming.

5. Ability to store more than 100 programs.

6. The micro-lubrication system regularly fills the guide rails and saves maintenance.

7. Special tungsten steel milling cutter, combined with micro-spray, makes the life of the milling cutter 20 times.

8. Customized high-speed spindle with Italian technology, 3-disc bearing, high precision and good stability.

9. The Z-axis uses a high-speed brake motor to prevent possible damage caused by the nose slipping after a sudden power failure.

10. Imported precision slider and precision lead screw

11. Pneumatic drawer for easy cleaning of debris

Technical parameters

|

Input power source |

380V/50Hz |

|

Total power |

5Kw |

|

Main spindle power |

3.5kw |

|

Main spindle speed |

0-18000rpm |

|

X axis processing range |

800mm |

|

Y axis processing range |

200mm |

|

Z axis processing range |

145mm |

|

X axis feeding speed |

0-9m/min |

|

Y axis feeding speed |

0-9m/min |

|

Z axis feeding speed |

0-9m/min |

|

X axis positioning accuracy |

0.05mm |

|

Y axis positioning accuracy |

0.05mm |

|

Z axis positioning accuracy |

0.05mm |

|

Machined surface roughness |

Ra 6.3um |

|

Dimension |

1300×1500×1700mm |

|

Weight |

800kg |

Previous

Variable angle cutting saw for aluminum profile window machine

MESSAGES