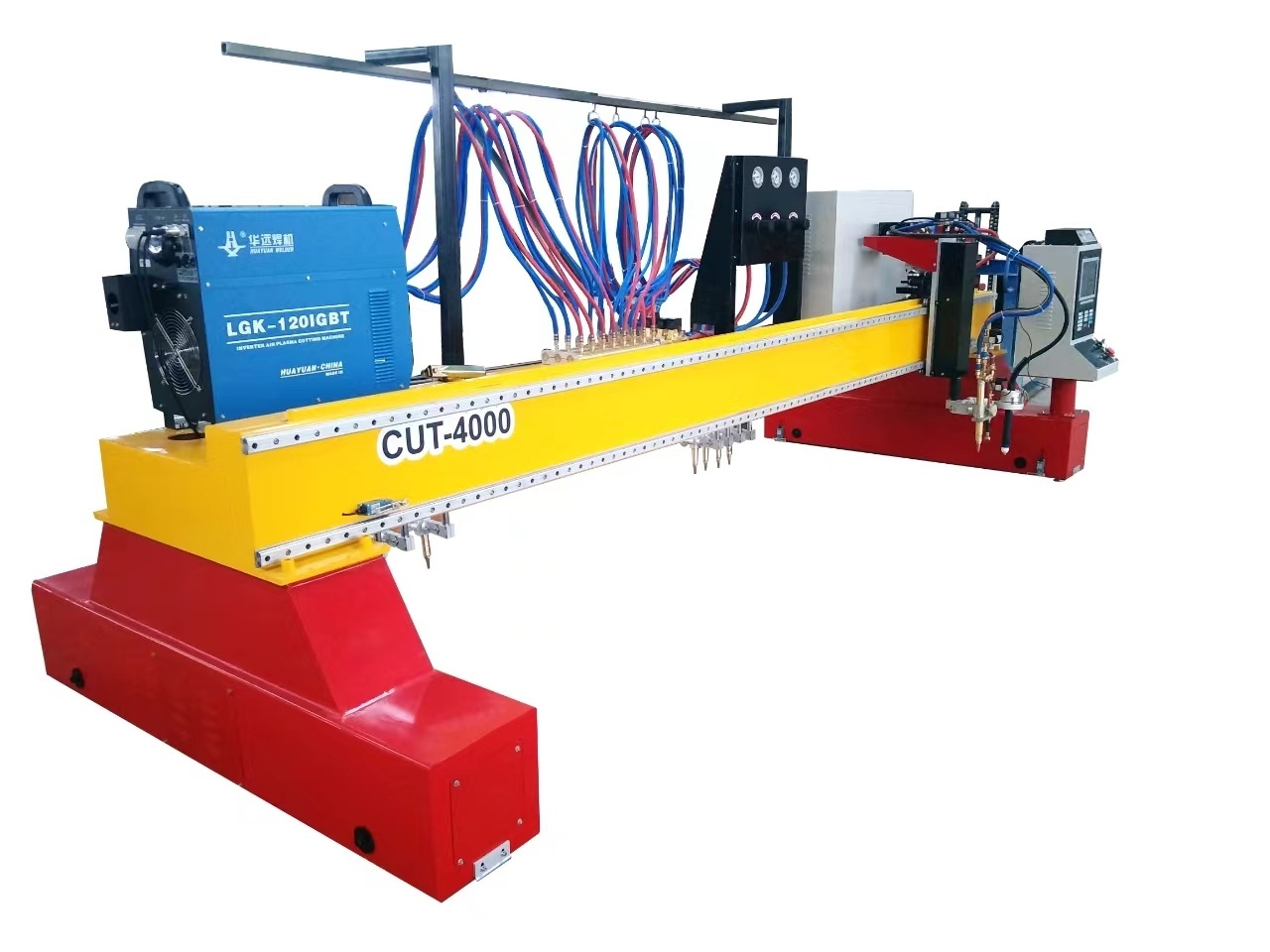

CNC Marking,Punching and Shearing Machine for Angle/ Flat/ Channel steel JBX1010

This machine is a device that integrates punching, typing and shearing for the angle steel, channel steel and plate.

key word:

Category:

ElectricTower Processing Machine

E-mail:

CNC Marking,Punching and Shearing Machine for Angle/ Flat/ Channel steel JBX1010

CNC Punching Marking &Shearing Machine for Angle/ Flat/ Channel steel

This machine is a device that integrates punching, typing and shearing for the angle steel, channel steel and plate. One machine can finish three functions for three kinds of metal materials. The structure of machine have some advantages:

Technology parameter:

| Model | JBX1010 | JBX1412 | |

| Angle size(mm) | ∠40×40×4 -∠100×100×10mm | ∠40×40×4 -∠140×140×12mm | |

| Channel size(mm) | 8,10,12,14 | 8,10,12,14 | |

| Flat bar size(mm) | 50x4-100x8 | 50x4-140x12 | |

| Processing length(mm) | 9000mm(Customized ) | ||

Punching ability | Punching Dia. (mm) | Round hole: 26, Long hole: 22x50 | |

| Punching force | 1100kN | ||

| Qty. of punch | 3pcs per side, total in two sides: 6pcs. | ||

Typing ability | Typing power | 630KN | |

| Quan. of typing dies | 4pcs | ||

| Size of the word(mm) | 14×10×19 | ||

| Quan. of words | 12pcs | ||

| Shearing | Shearing force | 1850kN | |

| Shearing mode | Single blade cutting | ||

| Qty. of axis | 3pcs | ||

| Feeding mode | CNC trolley feeding the materials | ||

| Feeding speed | 50-80m/minutes | ||

| Unloading mode | Pneumatic | ||

| Processing accuracy | Meet the requirement in GB2694-2010 | ||

| Programming mode | Auto CAD or programming with the software | ||

| Program function | Fault language display | ||

Machine structure:

This production line is composed by six parts: workpiece loading part, feeding part, host machine, finished workpiece unloading part, electrical control part, hydraulic power part.

1. Feeding part

Feeding part is composed by feeding channel and numerical control feeding car.

Feeding channel: is composed by conveyor roller, bracket, rack, precision liner guide way, lateral positioning wheels

Numerical control feeding car: is composed by servo motor, driven gear, synchronization belt, feeding car frame, clamping rod, clamping claw.

The workpiece firstly is manually sent into the clamp ,and the feeding clamp is automatically sent by the servo motor to the main machine for punching and shearing according to the instruction of the computer.

2. Host machine

This parts is composed by Pressing unit, Typing unit, Supporting unit, Side punching and Shearing unit.

Pressing unit:used to fix the workpiece, and prevent it’s deviation ,also to overcome the punching and shearing force. .

Typing unit:It consists of a fixed base of the machine, an oil cylinder that moves the base, a hydraulic power head cylinder, a four-position cylinder that realizes transposition of four character boxes, and a manual adjustment mechanism.

Supporting unit: When feeding materials, the support unit higher than the punching unit and typing unit to avoid the angle steel hitting the lower blade; When punching materials supporting unit lower than the punching unit and typing unit, to ensure the quality of typing, punching and shearing.

Punch unit:This unit has three punching position on every side. Three punching position can be equipped with the different diameter of punching head as the equipment of the customer. The punching positioning is driven by the servomotor through the ball screw and square rail to ensure the high positioning precision.

Shear unit:is composed by frame body, hydraulic power cylinder, upper knife box, down knife box, translation agencies, press parts, carry part. The machine can cut the angle steel, channel steel and plate by changing the different cutting dies.

Cut the angle steel Cut the channel steel. Flat cut plate steel.

The feeding device can prevent the angle steel from hitting the lower blade. Cutting three profiles can be achieved by changing different molds.

3. Finished workpiece unloading unit

Is composed by workpiece support roller and support shaft.

By press the button to turned-out workpiece on the left or right side (according to customer requirements).

4. Hydraulic power section

This machine adopts a stand-alone hydraulic station, which is convenient for equipment maintenance. The pipe joints are all connected by a ferrule type, which fundamentally avoids joint leakage. The hydraulic valve is connected by a valve block, and the plate valve and the cartridge valve are used at the same time. The piping is connected and the hydraulic system is tighter. Pipeline losses are minimized. System efficiency is fully utilized.

5. Electrical control

The electrical control system of the machine is advanced and reasonable, the workpiece programming is easy to learn and easy to operate.

The control software monitors the machine's operation at any time. When a fault occurs, the CRT will display detailed fault causes and treatment methods.、

Previous

CNC Steel Plate Drilling machine HD1280

MESSAGES