Aluminum profile CNC cutting machine center /cutting saw

key word:

Category:

Aluminum Window and Door Machine

E-mail:

Aluminum profile CNC cutting machine center /cutting saw

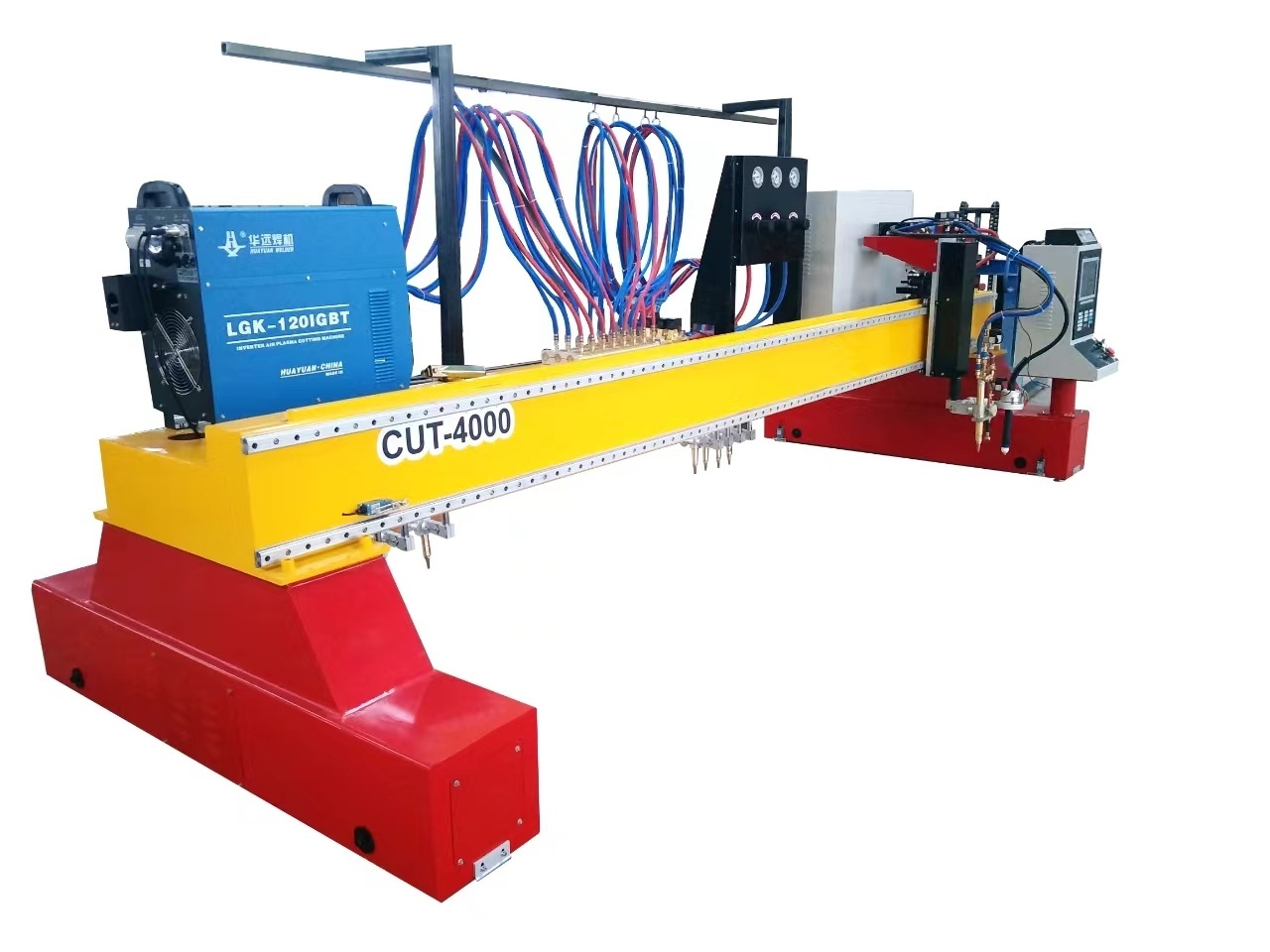

Aluminum profile CNC cutting machine center /cutting saw LJQZ-CNC-6800B

Features:

This cutting center line adopt the industry computer’s control system to finish higher cutting automation production.

For LJQZ-CNC-6500: It can automatic cut aluminum alloy profile in 45°and 90° .

For LJQZ-CNC-6800B: It can automatic fixed cut aluminum alloy profile in 45°.

The machineconsists of three parts: Feeding unit, Sawing unit and Discharging unit.

uPerformance characteristics:

The machine adopts industrial computer to control processing aluminum alloy profiles.The machineconsists of three parts: Feeding unit, Sawing unit and Discharging unit.

1.Feeding unit:

Auto delivery table can transport profile automatically and continuously, save time, save energy, efficient.

1.1Feeding mechanical arm adopts servo motor and precision helical rack drive, moving speed is fast, and the precision of repeating setting size is high.

1.2Feeding unit have equipment of auto measuring length of profile, can measure profile that error less than 80mm precisely, optimized cutting can be realized, and avoid to produce the unqualified products.

2.Sawing unit:

2.1It is equipped with the output device of wasted materials, can transport wasted materials tothe trash bin or trash pool continuously, avoid the accumulation of wasted materials and the pollution for the environment.

2.2 Inthe sawing box is equipped with the soundproof cotton to reduce the noise pollution efficient.

2.3Fixed 45°and 90°cutting,and vertical cut the profile from top to bottom, not only improve the cutting accuracy, but also avoid hurt; Cutting motor runs on the top of profile, this working way avoids the pollution to cutting motor from the cutting fluid and sawdust;

2.4 After cutting, saw blade separate from cutting surface of the profile during returning, avoids sweep profile when saw blade returns, if so, not only improve the cutting accuracy and the smoothness of cutting surface, but also avoid the wearing of saw blade due to the sweeping profile as saw blade returns, the using life of the saw blade can increase more than 30%.

3. Discharging unit:

3.1 Discharge robot adopts servo motor and precision helical rack drive, moving speed is fast, and the precision of repeating setting size is high.

3.2 Discharge table can transport profile continuously,improve work efficiency greatly, decrease the labor intensity.

3.3 Optional: can choose bar code printer,real-time printing Item ID, achieve process information identification, easy to manage materials.

Technical parameter:

|

Model |

LJQZ-CNC-6500 |

LJQZ-CNC-6800B |

|

Power sources: |

380V/50Hz |

380V/50Hz |

|

Total power: |

15KW |

12KW |

|

Working air pressure |

0.5~0.8MPa |

0.5~0.8MPa |

|

Spindle rotation speed |

2850r/min |

2850r/min |

|

Cutting angle |

45°,90°,135° |

45° |

|

The biggest cutting section (for single profile) |

90°: 130×150mm 45°: 110×150mm |

110×150mm |

|

Cutting length |

260~6500mm |

260~6800mm |

|

Dimension |

16000×4300×2600mm |

15000×4300×2600mm |

|

Weight of machine |

4500kg |

3500kg |

Previous

Variable angle cutting saw for aluminum profile window machine

MESSAGES