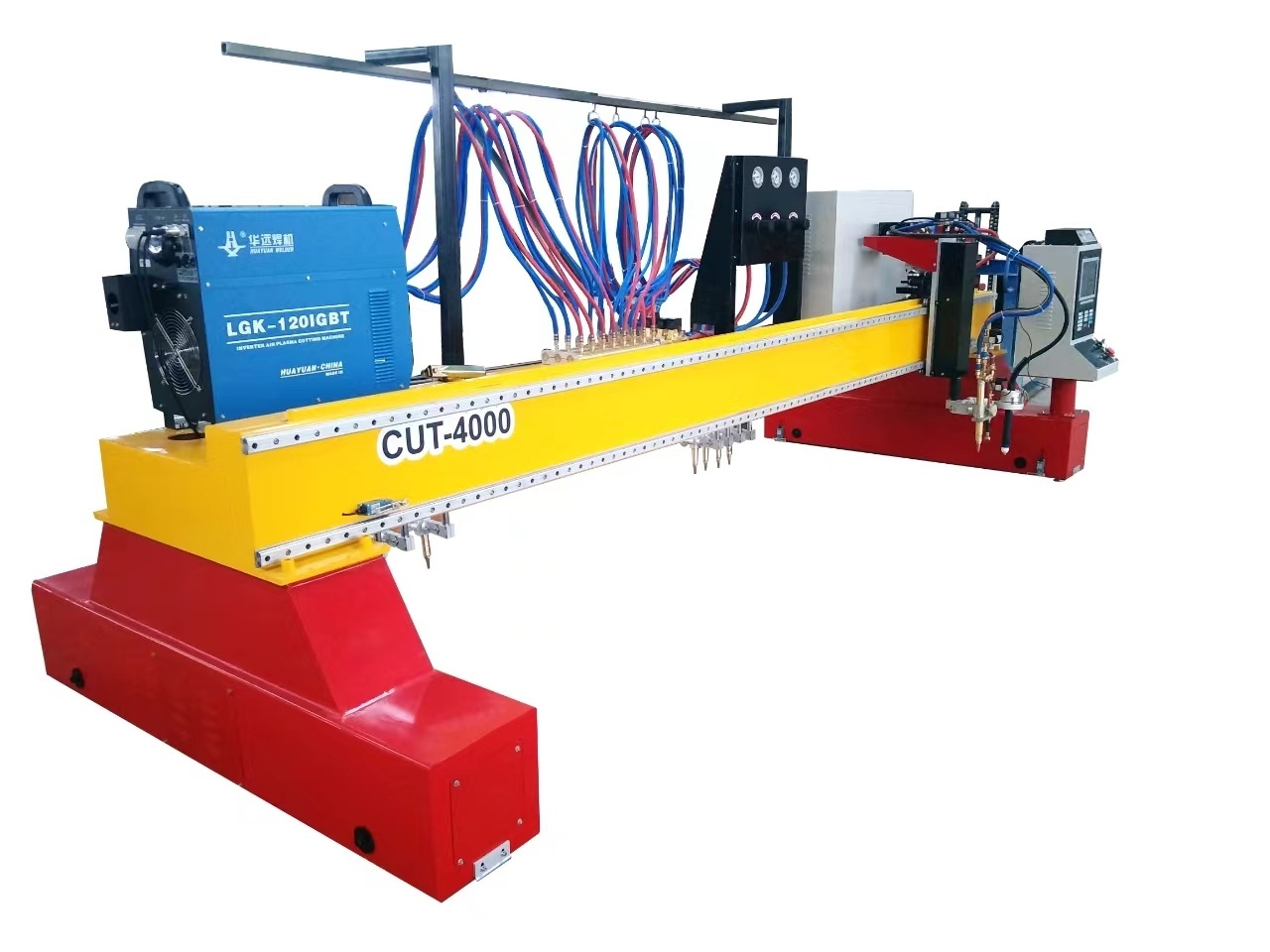

6-axis floor-rail industrial welding robot Arm span 1.5M 2M GR-WL300

The 6-Axis Floor-Rail Industrial Welding Robot provides a data link from design to automated welding production, enabling fully automatic welding of small batches and multiple varieties of steel structures.

key word:

Category:

Welding Robot

E-mail:

6-axis floor-rail industrial welding robot Arm span 1.5M 2M GR-WL300

Ground rail welding robot

Product Description:

The 6-Axis Floor-Rail Industrial Welding Robot provides a data link from design to automated welding production, enabling fully automatic welding of small batches and multiple varieties of steel structures. It supports seamless welding connections with mainstream 3D design software such as Tekla and Solidworks, and uses workpiece models to automatically calculate welds. Information; use advanced three-dimensional vision technology to automatically identify and locate the starting and ending positions of the weld and the wrapping angle position, automatically complete the robot's trajectory planning and programming, and automatically correct errors and deviations. The entire process does not require excessive manual intervention and does not require teaching. Programming to realize automation and intelligence of steel structure production and welding.

Technical Parameters:

|

Model |

GR-WL500 |

|

7 axis welding robot |

Arm span: 2000mm(customizable) |

|

Camera:3D,With high and low viewing distance functions |

|

|

Walking rail:Standard length: 12M & 15M (can be customized) |

|

|

Welding function:Support dual-machine collaborative welding function |

|

|

Repeatable positioning accuracy: ±0.05mm |

|

|

Voltage: 3 phase 380V |

|

|

Industrial robot control system |

|

|

Support TCP and camera hand-eye automatic calibration function |

|

|

Control servo:EtherCAT bus servo |

|

|

Operating mode:Teaching, online, remote |

|

|

Programmatically:Online teaching, process programming |

|

|

Welding wire diameter: 0.8mm、1.0mm、1.2mm、1.6 mm |

|

|

Gas flow: 15-20L/min |

Product display:

After-sales service:

1. Warranty.

——Farin Laser provides 2-year free warranty and provides customers with timely solutions.

2. Follow up.

——Farin Laser will regularly call or visit customers to perform equipment maintenance and archiving.

3. Online services.

—Farin Laser will respond to any questions from customers within 1 hour during working hours,

4. Overseas services.

——Farin Laser can provide overseas machinery installation, training, maintenance and other services.

Why choose us

① industrial computer with a 19 inch screen, it is more in line with the habit of using a computer

② dual cooling water chiller is more professional and can work for a long time

③ the new appearance design is more beautiful

④ pressure resistant and explosion proof water pipes and air pipes ensure the safe and stable operation of the machine under special circumstances

⑤ fully enclosed fireproof is a high and low temperature towline, which ensure the safety of the operation site

⑥ X axis flame retardant dust cover

⑦ highly flexible, anti-breaking cable that can shield external interference signals

⑧ fully automatic oiling system

⑨ high strength body leveling feet, more suitable for different venues of customers, ensuring high quality operational cutting

⑩ air cushion film cling film pearl cotton three-layer soft packaging stand

Previous

6-axis floor-rail industrial welding robot Arm span 2M(customizable)

MESSAGES