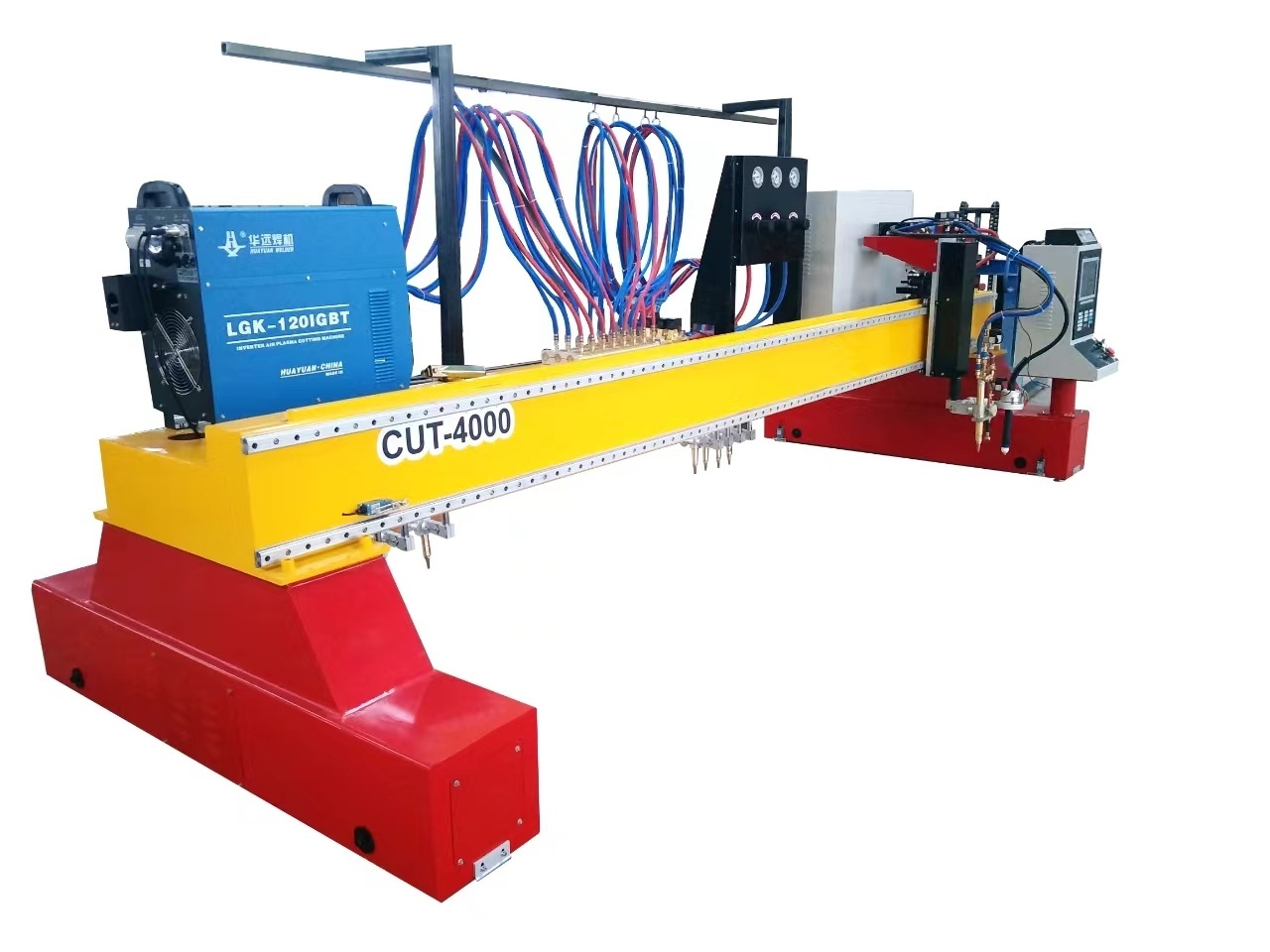

Gantry upside down welding robot workstation with high quality

9-axis industrial welding robot is a cutting-edge piece of technology designed to handle complex welding tasks with precision and efficiency. With its advanced capabilities, this robot is capable of welding in multiple axes simultaneously, allowing for seamless and uniform welds on a variety of materials. The robot's 9-axis design provides increased flexibility and range of motion, allowing it to reach into tight spaces and maneuver around obstacles with ease. This level of agility ensures that it can tackle even the most challenging welding projects with ease and accuracy. Equipped with state-of-the-art sensors and programming, this industrial robot is able to adapt to changes in the welding environment in real-time, making adjustments as necessary to maintain the highest quality welds. Its speed and consistency make it a valuable asset for any industrial welding operation looking to increase productivity and reduce costs.

key word:

Category:

H-Beam Steel Structure Processing Machine

Welding Robot

E-mail:

Gantry upside down welding robot workstation with high quality

Gantry upside down welding robot workstation

Product Description:

Gantry upside down welding robot workstation is a specialized tool used in manufacturing and welding processes. This workstation is designed to hold a welding robot in an inverted position, allowing for precise and accurate welding on various types of materials.

The gantry structure provides stability and precision, allowing the robot to move smoothly and efficiently across the workpiece. This configuration is particularly beneficial for welding tasks that require intricate and detailed work.

By using a gantry upside down welding robot workstation, manufacturers can achieve high-quality welds with minimal errors and inconsistencies. This technology helps to improve productivity and efficiency in the welding process, resulting in cost savings and improved product quality.

Overall, the gantry upside down welding robot workstation is a valuable tool for any manufacturing or welding operation looking to streamline their processes and achieve consistent, high-quality welds.

Technical Parameters:

|

Model |

GD-FY500 |

|

7 axis welding robot |

Arm span: 2000mm(customizable) |

|

Camera:3D,With high and low viewing distance functions |

|

|

Walking rail:Standard length: 12M & 15M (can be customized) |

|

|

Welding function:Support dual-machine collaborative welding function |

|

|

Repeatable positioning accuracy: ±0.05mm |

|

|

Voltage: 3 phase 380V |

|

|

Industrial robot control system |

|

|

Support TCP and camera hand-eye automatic calibration function |

|

|

Control servo:EtherCAT bus servo |

|

|

Operating mode:Teaching, online, remote |

|

|

Programmatically:Online teaching, process programming |

|

|

Welding wire diameter: 0.8mm、1.0mm、1.2mm、1.6 mm |

|

|

Gas flow: 15-20L/min |

Product display:

After-sales service:

1. Warranty.

——Farin Laser provides a 2-year free warranty and provides customers with timely solutions.

2. Follow up.

——Farin Laser will regularly call or visit customers to perform equipment maintenance and archiving.

3. Online services.

—Farin Laser will respond to any questions from customers within 1 hour during working hours,

4. Overseas services.

——Farin Laser can provide overseas machinery installation, training, maintenance and other services.

Why choose us

① industrial computer with a 19 inch screen, it is more in line with the habit of using a computer

② dual cooling water chiller is more professional and can work for a long time

③ the new appearance design is more beautiful

④ pressure resistant and explosion proof water pipes and air pipes ensure the safe and stable operation of the machine under special circumstances

⑤ fully enclosed fireproof is a high and low temperature towline, which ensure the safety of the operation site

⑥ X axis flame retardant dust cover

⑦ highly flexible, anti-breaking cable that can shield external interference signals

⑧ fully automatic oiling system

⑨ high strength body leveling feet, more suitable for different venues of customers, ensuring high quality operational cutting

⑩ air cushion film cling film pearl cotton three-layer soft packaging stand

Previous

9-axis industrial welding robot ground rail 6M 9M 12M 15M 22M

MESSAGES