CNC Aluminum profile Rolling and Bending machine

it's used for bending processing for aluminum profile, steel pipe, steel frame for different industry.

key word:

Category:

Aluminum Window and Door Machine

Industrial Aluminum Profile Machine

E-mail:

CNC Aluminum profile Rolling and Bending machine

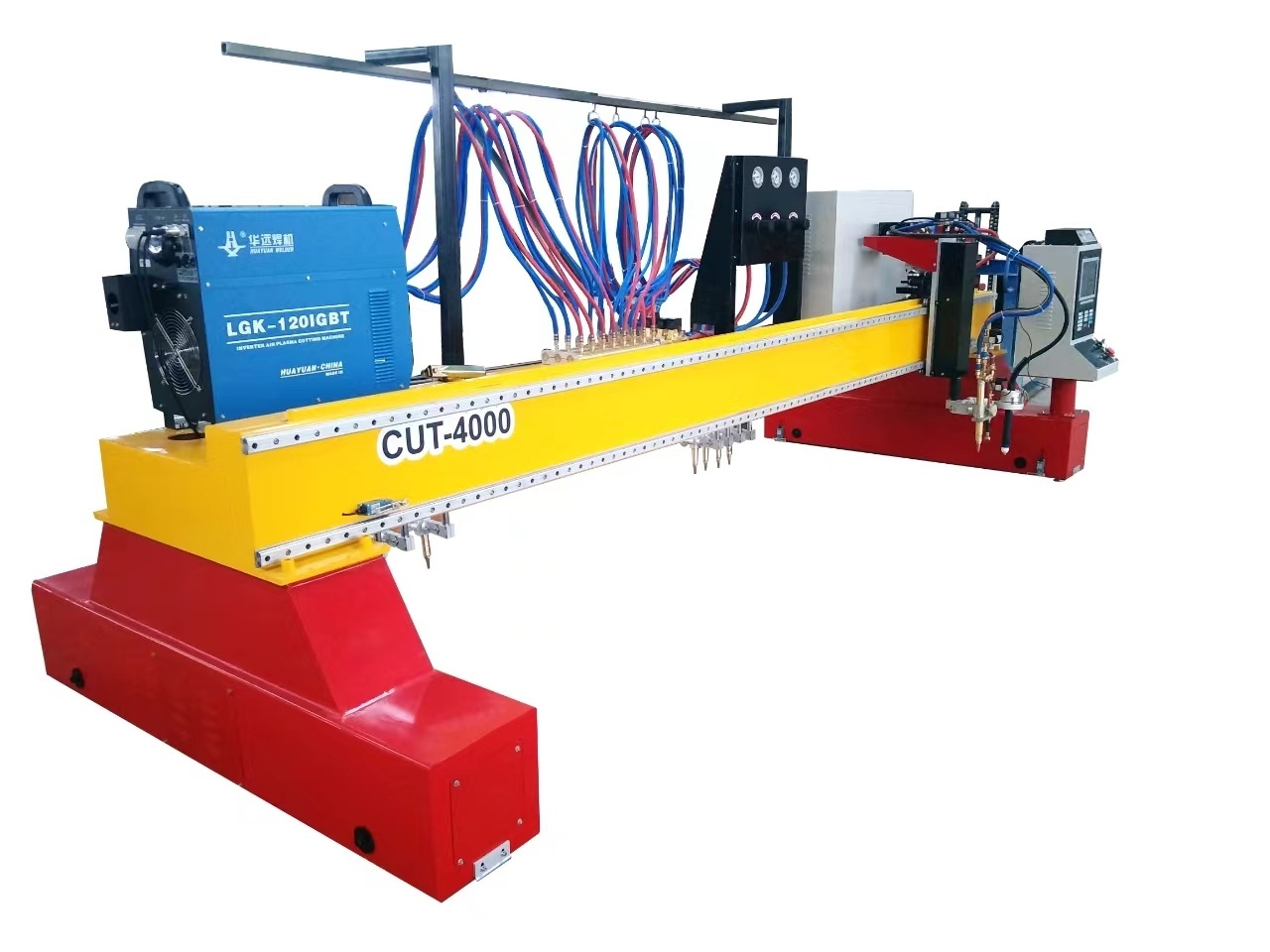

Full Automatic CNC Rolling Benging machine LWYJ-CNC-20T

Technology parameter of Arc bending machine

Function:

This kind of CNC bending machine adopts imported oil pressure system YUKEN -JAPAN, it features stable and efficient, mechanical structure without gap connection, and is widely used in aluminum alloy doors and Windows, automobile industry, aerospace and aviation, high-speed railway, wind power generation, ships, large buildings, bridges, machinery and other non-standard metal profile bending processing.

Features:

1. For Processing for different arc, it can realize multi-radius bending single molding (multi-curvature), effectively improving processing efficiency and saving labor

2. For ordinary arc processing, can achieve one processing completion, high efficiency. It can also be formed for many times according to the actual situation, effectively ensuring the appearance of the arc and the practicality of the equipment.

3. The independently developed hydraulic system keeps the equipment positioned at 20 tons with repetitive control accuracy under the pressure of 0.1mm.

4. Accurate radius (R) control and easy continuous processing of multiple arc and complex drawings.

5. Graster ruler: use double drive grille ruler, equipped with anti-interference module, good arc repetition.

6. The X-axis direct connection motor is controlled by Emexin: high positioning accuracy, constant torque, not changing because of the speed.

7. CNC control system, completely solve the smoothness and symmetry of different curvature transition;

8. Humanized control system, flexible, simple, a look to understand, a use will be; completely solve the dependence on skilled workers.

9. Exquisite mold design technology, the perfect solution to solve the product wrinkle, scratch, distortion, subsidence and other quality problems, to meet your high quality requirements for the product.

10. Unique core algorithm, rich rolling processing parameters, simple operation, simple and practical.

11. Automatic feeding calculation to reduce your material waste.

Technology Parameter:

|

Model |

LWYJ-CNC-20T |

|

Power supply |

380V 50Hz |

|

Input power |

5.2Kw |

|

Hydraulic stress |

20T |

|

Max diameter of roller |

300mm |

|

Main shaft speed |

1-15r/min |

|

Shaft diameter of main shaft |

60mm |

|

Center distance of fixed shaft |

350-750mm adjustable |

|

Y axis push force |

20 T |

|

Y axis hydraulic pump location precision |

|

|

Main Torque of X axis |

2500N.M*3=6000N.M |

|

Y axis travelling |

220mm |

|

Profile processing range |

150*150mm (H*W) |

|

X axis Positioning accuracy |

<0.5mm |

|

Y axis repeat location precision |

±0.1mm |

|

Min. bend radius |

R=100mm (inner arc) |

|

Main Machine size |

1300*1100*1500mm |

|

Operation panel size |

500*510*1500mm |

|

Weight |

1000Kg |

Next

Previous

Nothing

Next

MESSAGES