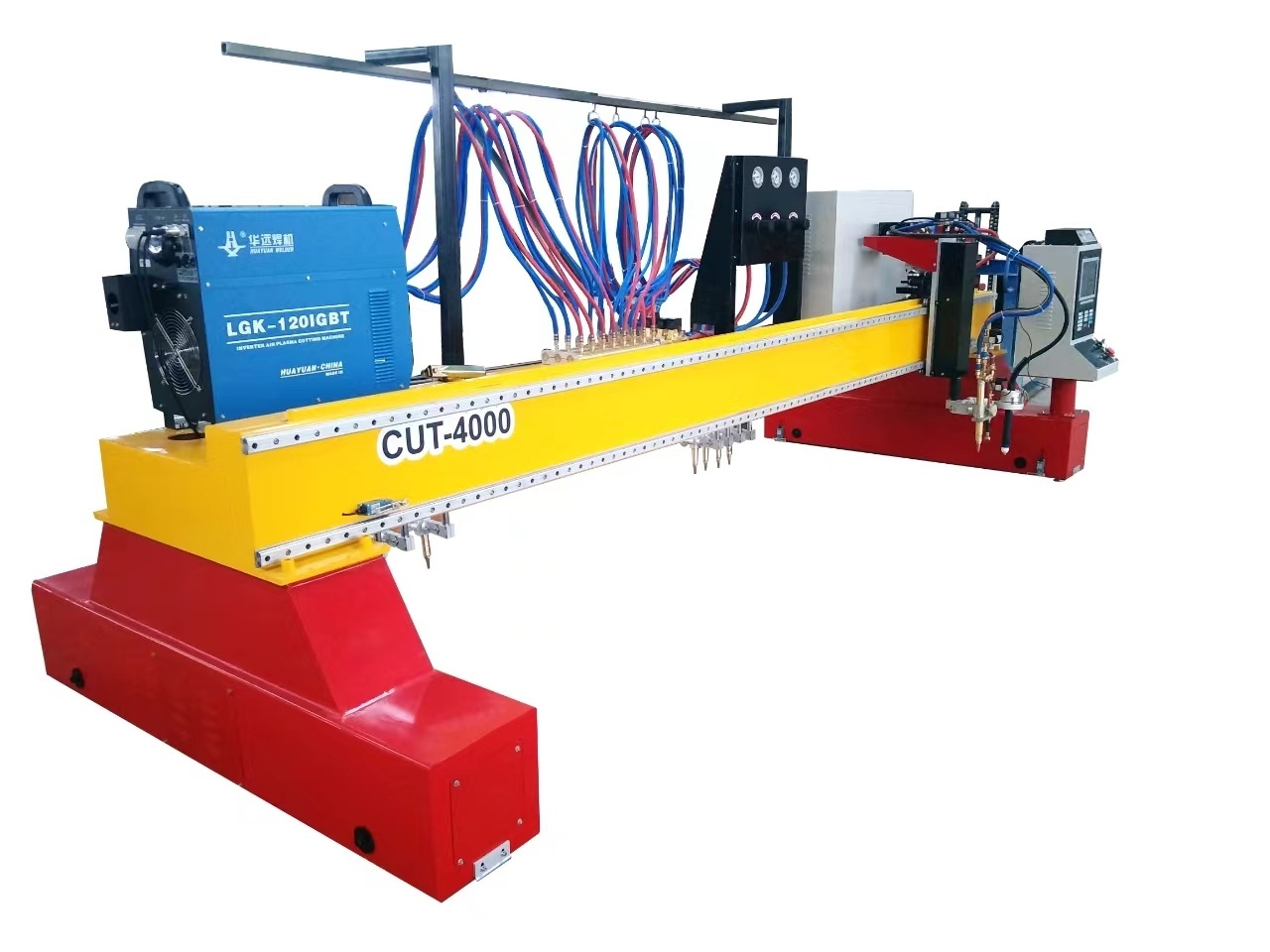

PVC PP PE Soft Curtain Sheet Extrusion Line

it's used for produce the PE PP PVC sheet.

key word:

Category:

Plastic Extrusion Machine

E-mail:

PVC PP PE Soft Curtain Sheet Extrusion Line

PVC PP PE Soft Curtain Sheet Extrusion Line

PE/PP sheet has the characteristics of non-toxic, flame resistance,flexibility,good tensile and abrasion resistance. It is being widely used in the medical industry,food industry,chemical industry,clothing industry,packaging industry,electronics industry and so on.

PE/PP sheet has the features of high impact, heat resistance, non-toxic, smooth surface, corrosion resistance, excellent electrical insulation performance and so on. It is being widely used in environmental protection industry, food industry,chemical industry,electric power industry and other industries.

PE/PP Board/sheet Size

Thickness: 0.5-30mm

Max width: 3000mm (sheet can be wound.)

Product description:

1. Applied Resin: PU granule:PVC

2. Product: PU soft tube:PVC soft curtain sheet

3. Specification: 400*1-5mm (width*thickness)

Environmental conditions

1、Location: Indoor

2、Power source: No dangerous area

3、Humidity level: 85%, non-condensing

4、Temperature: 0-40℃

5、Protection mode: Earth

6、Power Voltage: 385V 50Hz three phase, four line

7、Total Power: 120KW about

Conditions of usage:

1、Power source: three-phase, four-wire, 380V, 50HZ

2、Circulating water: ≤20℃, ≥0.3Mpa, 2-4m³/h

3、Compressed air: >0.5MPa, 0.4m³/min.

4、Installed gross power: about 120KW

5、Power consumption: about 45-50KW/h

6、Central height of the extruder: 1000mm

7、Equipment installed dimension(L×W×H): 12000mm×900mm×3000mm

8、Direction of the operation: from right to left

Equipment list:

|

No |

Item |

Quantity (set) |

|

1 |

Auto feeder and dryer |

1 |

|

2 |

SJ-75/35 Single Screw Extruder 75/28 |

1 |

|

3 |

Extrusion mould |

1 |

|

4 |

Three rollers calender |

1 |

|

5 |

Mould temperature controller |

1 |

|

6 |

cooing bracket and Edge Cutting Unit |

1 |

|

7 |

Haul off machine |

1 |

|

8 |

Double working position winder |

|

Technology Parameter:

1. Automatic feeding machineJL100

|

Deliverability |

300 kg/h |

|

Delivery Distance |

4 m |

|

Volume |

100L |

|

Air Pump Power |

2kw |

2. Single-screw Extruder SJ75/28

|

1)Model |

SJ75/28 |

|

—— Capacity |

140-200kg/h(PVC) |

|

—— Central height |

1000mm |

|

2)、Screw |

|

|

— diameter |

75mm |

|

— Material |

38CrMoAlA |

|

— Surface treatment |

Nitriding, Depth 0.50~0.70mm |

|

3)、Barrel |

|

|

——Material |

38CrMoAlA |

|

——Inner surface treatment |

Nitriding, Depth 0.50~0.70mm, Honing |

|

——Heating zones |

4 |

|

——Heating method |

cast aluminum heating band |

|

——heating power |

3KW×4=12KW |

|

——cooling system |

fan cooling |

|

——cooling power |

0.25KW×3 |

|

——temperature range |

50~300℃ |

|

——Temp. control meter |

Omron Brand |

|

——Screw place |

Zhoushan ,China |

|

5)、Main motor |

|

|

——Power |

55Kw |

|

——Motor type |

Siemens Beide |

|

——Rotate speed |

75~1500 r/min |

|

—— control style |

(ABB)By inverter |

|

——connection with gear box |

by coupler |

|

6)、Gear box |

|

|

—— output torque |

10186 Nm |

|

——material of box |

HT200 Casting |

|

— Teeth clench |

Hard surface clench |

|

——Teeth material |

20CrMnTi |

|

——Teeth surface |

Carburizing+gear grinding |

|

——Shaft material |

40Cr |

|

——Lubricant system |

Oil pool infiltration + forced circulation oil supply lubrication |

|

——cooling of lubricant oil |

Water cooing, cooling device outside gear box |

|

——Seal glue |

Imported brand |

|

7)、connection part to mould |

|

|

——connection |

Flange+screw |

|

8)、Electricity cabinet |

|

|

——Wire |

three-phase, four-wire |

|

——Brand |

Main inverter: ABB Temperature control: Omron Brand Contactor: Siemens Breaker: Siemens Relay: Siemens; Middle relay: Omron |

3. PVC Sheet mould

|

Structure |

cloth hanger |

|

Material |

2Cr13 |

|

Heating method |

Heating plates |

4. Slope Three Rollers calender (Vertical type)

|

1 |

Roller size |

mm |

3×Φ400×1100mm |

|

2 |

Rough of roller surface |

|

Ra≤0.025um |

|

3 |

surface hardness |

|

HRC≥50 |

|

4 |

Depth of chrome plating |

|

≥0.08mm |

|

5 |

transmission |

|

Independent transmission |

|

6 |

Gear and motor |

|

Made in China |

|

7 |

Motor power |

|

3×1.1KW |

|

8 |

Controller |

|

ABB inverter |

|

9 |

Adjustment of roller gap |

|

Mechanical worm adjustment, safety emergency stop switch, synchronous control system |

|

10 |

Bearing |

|

HAERBIN Bearing |

|

11 |

Style |

|

Verticaltype |

5. Mould temperature controller

|

Temperature range |

35-160℃ |

|

Temp Accuracy |

≤±1℃ |

|

Control method |

Independent recycling |

|

Power |

3*12KW |

|

Control valve |

Pneumatic angle seat valve |

6. Cooing bracket and Edge Cutting Unit

|

roller |

Stainless steel roller, polished, U shape end plate fixed, no clings |

|

structure |

Square tube frame segment |

|

length |

8 meters |

|

Blade |

Alloy |

7. Haul off machine

|

Rubber Roller size |

Φ200mmx1100mm |

|

Quantity |

1 pair , upper and lower , synchronous |

|

Driving |

inverter decelerating motor |

|

Motor power |

1.5kw |

|

Press style |

cylinder |

|

Control |

ABB |

8. Single working position winder

|

control |

Tension controller |

|

roller change style |

Manual |

|

Roller diameter |

300-900mm |

|

Max.width of roller |

400mm |

Previous

Waterproof PVC WPC Wall Panel Profile Production Line

MESSAGES