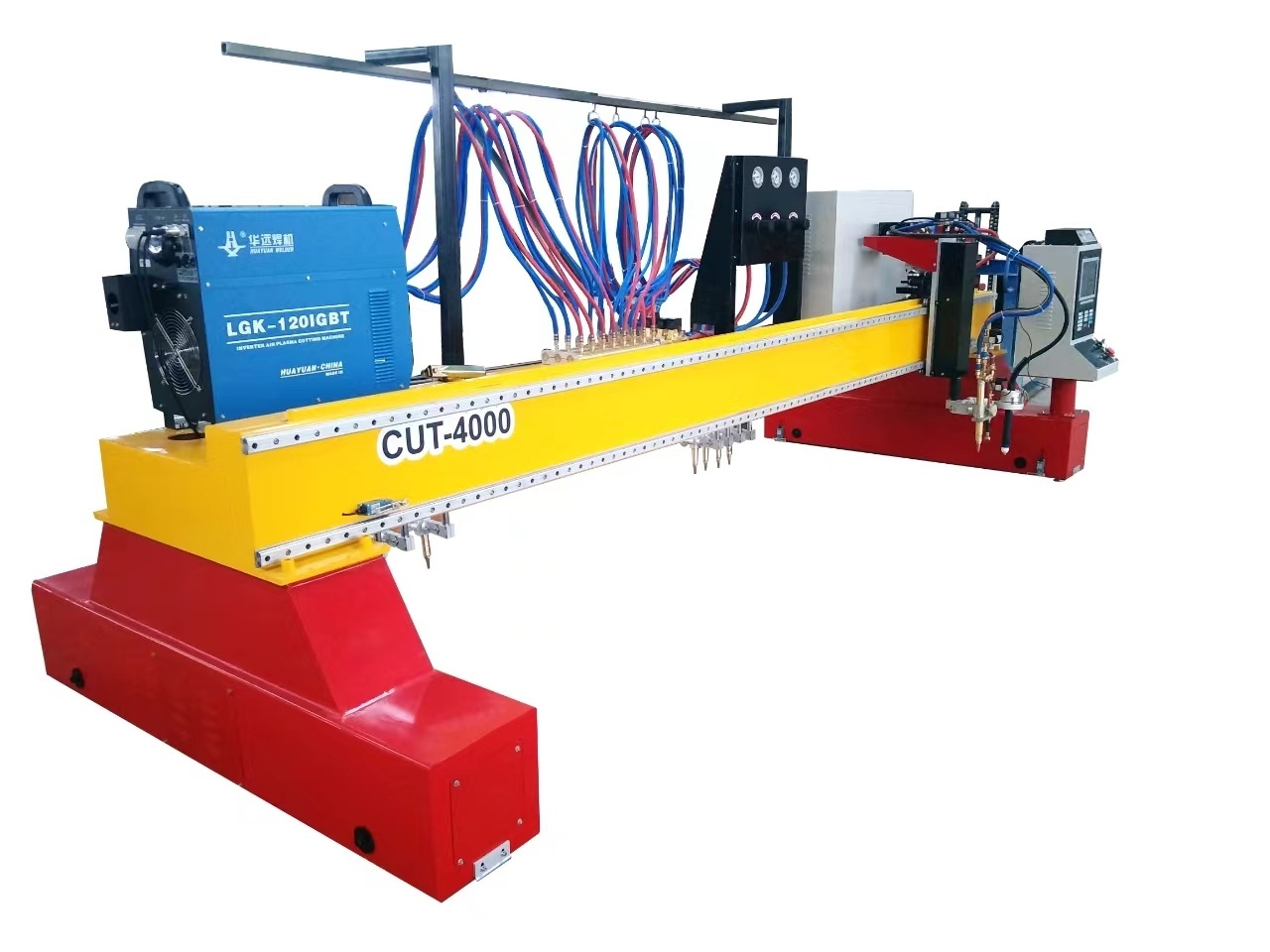

CNC Lock-hole Milling Machine for H-beams

The CNC Lock-hole Milling Machine for H-beams is a specialized tool designed for accurately milling lock holes in H-beams used in construction and steel structure fabrication. Equipped with a computer numerical control (CNC) system, this machine offers precise control over the milling process, ensuring consistent and high-quality results.

key word:

Category:

CNC High Speed H Beam Drilling Machine

Steel Structure Processing Machine

E-mail:

CNC Lock-hole Milling Machine for H-beams

BMSeries CNC beveling Machine for H-beams

The CNC Lock-hole Milling Machine for H-beams is a specialized tool designed for accurately milling lock holes in H-beams used in construction and steel structure fabrication. Equipped with a computer numerical control (CNC) system, this machine offers precise control over the milling process, ensuring consistent and high-quality results. Its robust spindle and cutting tools are capable of creating precise lock holes with smooth edges and tight tolerances, meeting the strict requirements of structural engineering. With its automated operation and customizable programming, this machine enhances efficiency and accuracy in the production of H-beams, making it an essential equipment for manufacturers and construction companies seeking reliable and high-performance solutions for lock-hole milling tasks.

◆Apply scope:

Special machine for milling the lock-hole of end of H – Beams.

◆Product structure characteristics:

1. The machine is single-sided, double-sided and four-sided, each column is equipped with a three-axis milling

power head, which can install three different milling cutters. The milling head cuts both ends of H-section steel from

bottom to finish the arc groove processing of the end face, groove and web of the wing plate.

2. Double columns/four columns are installed on longitudinal and transverse NC sliding tables respectively. When

processing H-beams of different specifications, they can be adjusted automatically only by inputting machine tools with

specifications and parameters, and can milling H-beams with inclined end faces.

◆Technical parameter:

|

Модель |

BM38/6 |

BM38/12 |

|

|

Workpiece dimensions |

Width of the web(mm) |

220-1000 |

|

|

Height of the flange(mm) |

100-600 |

||

|

Thickness of the flange(mm) |

10-38 |

||

|

Title of the end face(mm) |

≤300 |

||

|

The length(mm) |

≥400 |

||

|

Three-axis drilling head |

Quantity |

2 |

4 |

|

Rotation speed of the spindle(rpm) |

400 |

||

|

Power of the spindle motor(KW) |

2×7.5 |

4×7.5 |

|

|

Up-down speed (Frequency conversion, CNC) (m/min) |

50-500 |

||

|

Power of the up-down motor (KW) |

2×1.5 |

4×1.5 |

|

|

Sliding table |

Longitudinal slide stroke (mm) |

300 |

|

|

Transverse slide stroke(mm) |

1050 |

||

|

Slide Speed (Frequency Conversion, CNC)(m/min) |

150-1000 |

||

|

Power of the sliding motor(KW) |

2×0.25 |

4×0.25 |

|

|

Vertical clamper |

Vertical clamping speed(m/min) |

450 |

|

|

Power of the vertical clamping motor |

2×0.37 |

4×0.37 |

|

|

Gas-liquid boost device |

Boost ratio |

11:1 |

|

|

Clamping force |

3.5-8 |

||

|

Automatic milling deep iron |

Amount of regulation |

0-40 |

|

|

Power of the motor |

2×0.04 |

4×0.04 |

|

|

Outer and inner roller conveyor |

Length of outer roller conveyor (mm) |

1×5060 |

2×5060 |

|

Conveying speed (Frequency conversion) |

2.5-20 |

||

|

Power of the outer conveyor motor(KW) |

0.75 |

2×0.75 |

|

|

Power of the inner conveyor motor(KW) |

0.4 |

2×0.4 |

|

|

Power of the motor for supporting roller(KW) |

2×0.09 |

4×0.09 |

|

|

Power of motor for titling roller conveyor |

|

4×0.09 |

|

|

Size of machine (L ×W×H) (m) |

7.3×2.9×2 |

14.6×2.9×2 |

|

|

Weight of machine (kg) |

5000 |

10000 |

|

Previous

CNC Three-dimensional Drilling machine

MESSAGES